Service scope and content

Full-cycle technical support

• Installation and debugging: Covers equipment installation and debugging work, ensuring that the equipment can be installed correctly and start operating; calibrates parameters to ensure that the equipment parameters are accurate and reasonable; and focuses on solving potential problems with equipment stability to ensure stable operation.

• Operation training: Provides on-site or online equipment operation training, allowing relevant personnel to choose a learning method according to the actual situation; interprets the maintenance manual to help users better understand the key points of equipment maintenance; conducts safety regulation drills to strengthen personnel's safety awareness during equipment operation and avoid accidents.

• Fault diagnosis:

Able to troubleshoot problems in hardware (such as structural parts, sensors, etc.) and software (including control programs, communication protocols, etc.) in real time, quickly locate the fault, and provide a basis for subsequent repair work.

• Preventive maintenance: Conduct quarterly equipment inspections and annual system health checks to closely monitor the operating status of equipment and systems; also provide reminders for consumable replacement, prepare in advance to avoid affecting the normal use of equipment due to consumable problems, thereby extending the service life of equipment and reducing the probability of sudden failures.

Special services

• Production line optimization: Based on the results of production efficiency data analysis, provide relevant suggestions for upgrading the automation process, enhance the automation and intelligence level of production, and better adapt to production needs.

• Emergency support: Provides global 7x24-hour on-site response services. No matter when and where customers encounter emergencies, professional personnel can be dispatched to the site in time to quickly solve problems and minimize the impact on production and other businesses.

Service scope and content

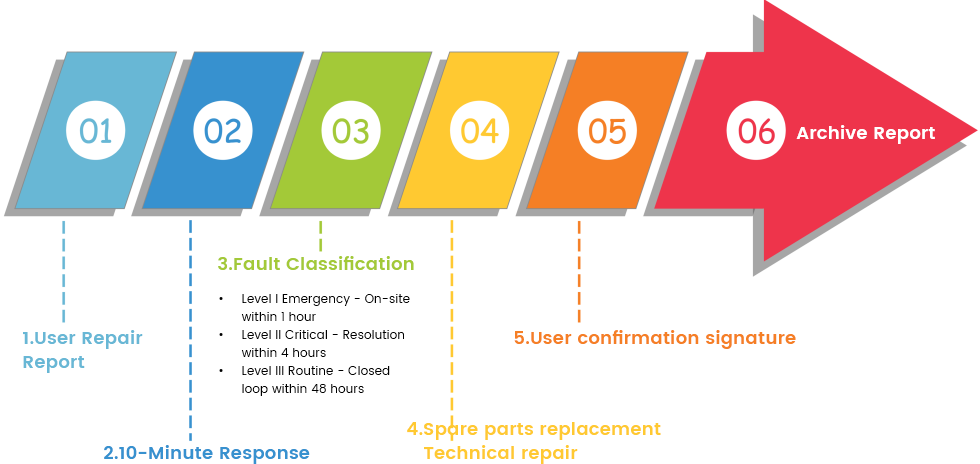

Standardized process

Multi-channel access

• Telephone response ≤10 minutes

• On-site arrival in the same city ≤1 hour

• Cross-regional on-site arrival ≤24 hours

• Fault resolution rate ≥95% (within 72 hours),Within 72 hours of receiving customer fault feedback, the service team can effectively eliminate the fault and restore normal business operation

Service commitment and guarantee

Telephone response

On-site arrival in the same city (Level I)

Fault resolution rate

1-3 years free warranty for the whole machine (excluding consumables), and core components (servo motors, controllers) extended warranty for 1-3 years *Note: Specific details shall be subject to the contract.

Value-added services

Customized development

ODM/OEM cooperation: Non-standard robotic arm fixture design, special communication protocol adaptation.

Data services

Cloud monitoring of equipment operating status (such as predictive maintenance reports, energy consumption analysis)

Self-service resource library

White Paper on Micro-Special High-Frequency Switching Matrix

Size: 513.3KB

date: 2025-07-31

Service Hotline

Service Hotline